A systems approach to the mild hybrid powertrain – Ricardo/Valeo

Contributor Richard Gordon, Technology Group, Ricardo Consulting Engineers Ltd, Shoreham-by-Sea, West Sussex, UK

Achieving improved fuel consumption and emissions legislation beyond Euro IV will involve increasing use of new powertrain technologies if customer requirements for performance, cost and reliability are to be retained. Ricardo is investigating these technologies in collaboration with Valeo via the physical application of mild hybrid systems to a highly downsized HSDI diesel engine within the popular “C” class vehicle sector. This research programme aims to demonstrate less than 4 litres per 100 km fuel consumption, half of the current Euro IV emissions levels and strong vehicle performance whilst assessing the cost / benefit ratio of each new technology. This can only be achieved through the integration of both the hardware and the control of such powertrain systems.

The Automotive Manufacturers Association (ACEA) has agreed to target a fleet average fuel consumption of 140 g/km CO2 throughout Europe for the year 2008. A current, typical OEM average vehicle fleet produces approximately 185 164 g/km CO2 (compiled from published data). Therefore, the introduction of popular vehicles with significantly less fuel consumption than is currently achieved will be required. Ricardo believes low cost, mild hybrid systems coupled with high specific output, downsized engines and an integrated control approach can offer the market requirements in the necessary timescale. The Ricardo Integrated Research Programme (IRP) i-MoGen programme, in collaboration with Valeo, is integrating these systems into a “C” class vehicle. This offers Ricardo the ability to demonstrate the powertrain capabilities, validate modelling tools and to develop innovative solutions required for such systems. More importantly, this is an opportunity to assess the cost / benefit ratio for such technologies in order to give realistic advice for future OEMs and Tier 1 suppliers product planning.

The programme has been configured to make use of Ricardo rapid engineering tools and techniques to ensure that it is completed within one year. Currently the vehicle and powertrain systems are undergoing calibration towards the final targets.

Systems overview

The selection of technology for this programme is summarised in Figure 1. There are a number of options to achieve low vehicle fuel consumption and in this case, a downsized HSDI diesel engine was chosen as a starting point. However, low speed torque and hence driveability can be an issue with this solution and so further decisions had to be made to overcome this. Ricardo chose the mild hybridisation approach due to the significant added functionality such a system brings, including regenerative braking, energy management and instant torque addition delivery.

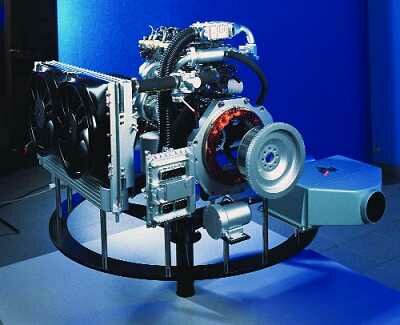

Given these decisions, the Ricardo mild hybrid vehicle concept consists of the technologies shown in Figure 2, which also indicates the approximate packaging positions in the vehicle:

These technologies have been used for the following reasons:

• The down-sized engine offers between 20 and 25%per cent fuel consumption savings during part load driving conditions whilst giving similar peak torque and power output compared to a current 2.0 litre turbo diesel engine. A five speed manual transmission is used.

• The Valeo water cooled Flywheel Mounted Electrical Device (FMED) and its inverter, together with a Nickel Metal Hydride battery developed with SAFT offers efficient 42V power generation, regenerative braking, torque boost (to assist the engine at lower engine speeds) and “stop and go” functionality. Together, these functions can offer over 8% fuel consumption benefit for the European drive cycle.

• The Ricardo supervisor control system performs intelligent energy management whilst optimising emissions, fuel consumption, battery state of charge and NVH considerations via cost/benefit based objective function calculations. Compared to simple rule based systems, this can give up to 5% fuel consumption gains during some operating conditions. This system is essential to realise the maximum benefits of the powertrain

• Intelligent engine cooling, developed with Valeo, couples the efficiency of a 42 V water pump and 42 V radiator fans and optimises the engine warm up, part load and full load cooling system operation. This is expected to offer 2 to 4%per cent fuel consumption savings. Valeo 42 V Heating, Ventilation and Air Conditioning systems (HVAC) combines 1.5 kW electrical heating and 3.3 kW electrical compressor for air conditioning to ensure cabin comfort. De-coupling from the engine ensures flexibility in operation and intelligent control minimises the energy consumption.

• A close coupled passive de-NOx and oxidation catalyst is sufficient to achieve the NOx targets as high levels of cooled EGR are used. This has a minimal impact on fuel consumption. An electrically heated Diesel Particulate Filter (DPF) is used to almost totally eliminate particulate emissions. Cleaning of the filter (regeneration) is to be achieved without the need for fuel additives or with additional fuel injection.

• The base vehicle used is a standard Opel Astra which was a 2.0 DTI, model year 2000 version. No weight reduction was applied to this base vehicle as that was considered beyond the scope of this programme. It is clear that vehicle weight will have to reduce in this sector for 2008 and so Ricardo has used a test inertia of 1130 kg for this vehicle which represents the lower band of vehicle weights in this class.

• Simulation tools have been developed to assess hardware parameters, develop and optimise control strategies and generate drive cycle emissions and performance data. This is the Ricardo Integrated Powertrain Model (IPT) (1) which made a significant contribution to the development of the supervisor control system by being able to model all of the significant vehicle systems in real world driving conditions.

It is important to note that the FMED system has become an enabler that makes the use of other systems possible. For example, the down sized engine suffers with low torque output at speeds below 1500 rev/min. Therefore, to ensure good driveability, the FMED is used to provide torque boost within that lower speed range. This overcomes the traditional difficulties of a down sized engine so allowing it to improve part load vehicle efficiencies. (Other means exist to achieve this such as electrically assisted boosting systems which were not specifically looked at in this programme.)

Due to the high electrical power output of the FMED, the use of 42V electrical systems such as efficient pumps, fans and HVAC equipment becomes possible allowing improved sub-system control. Also, with electrical energy storage and supervisory control, intelligent energy management is possible. For these very reasons, Ricardo’s main objective was to produce a fully integrated mild hybrid vehicle to assess accurately the impact these technologies can have on such a vehicle.

Conclusions

The objective of this programme was to demonstrate mild hybrid vehicle technologies achieving future emissions legislation whilst giving ultra low fuel economy and excellent performance. In addition, to be able to assess the cost of these technologies for future product planning. Whilst this Ricardo and Valeo collaborative programme is on-going the following can be summarised:

The down sized engine is the most effective route to producing a step change in vehicle drive-cycle fuel consumption without reducing vehicle performance or emissions compliance. Over 20% reductions are possible. Torque deficit below about 1500 rev/min can be overcome using a variety of systems including a Flywheel Mounted Electrical Device (FMED) or electrically assisted boosting systems depending on the application. This programme has so far demonstrated a 1.2 litre 4 cylinder engine producing power and peak torque similar to current production 2.0 litre HSDI engines whilst achieving significantly lower emissions and considerable weight savings. This engine is now integrated within the programme mild hybrid vehicle. Cost estimations for this engine indicate that the base engine and fuel injection system are no more expensive that current HSDI engines. Low speed torque addition systems obviously increase the costs but depending on the route taken this is expected to be competitive in the future market place.

|

|

| A fully intergrated mild hybrid system |

The use of mild hybridisation and supervisory control systems has been demonstrated in simulation and is now being optimised in hardware. The functionality these systems bring to the vehicle is seen via modelling to offer a further 8 to 13% fuel saving by intelligent energy management. The engine downsizing easily offsets weight additions by these systems.

Active sub-systems such as intelligent cooling, electric HVAC and electric power steering give further potential fuel savings, albeit in the range of a few percentage points. It is important that such systems, which do not necessarily give large fuel consumption savings, bring significant additional functionality. As shown above, this is often the case, which improves the cost / benefit ratio such that they do become possible additions to the vehicle.

Combined, these technologies have been calculated to achieve less than 4 litres / 100 km fuel consumption (cold), half Euro IV emissions compliance and significant performance feel in a “C” class vehicle. System data recorded so far indicates that this is indeed possible.

The practical approach that has been taken in this programme has made use of Ricardo tools and techniques, developed further modelling capability and found innovative solutions for the design and application of mild hybrid systems. Future programme effort will be focused on optimising the vehicle for real-world driving conditions and comparing measured with modelled data for the mild hybrid vehicle systems operation.

|