Articles

Torotrak on Track

Author: Mac McColgan

Source: Autoindustry

Publication Date: 20th January 2003

Torotrak, formed in 1998, are a British company based in Leyland, Lancashire. Their origins are can be traced back as the Sixties when BGT first became involved in Continuously Variable Transmission technology by funding the development of the Perbury CVT.

Torotrak, formed in 1998, are a British company based in Leyland, Lancashire. Their origins are can be traced back as the Sixties when BGT first became involved in Continuously Variable Transmission technology by funding the development of the Perbury CVT.

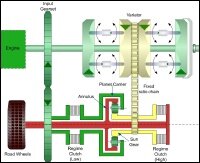

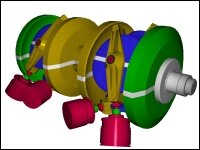

Conventionally, power from a vehicle's engine reaches the wheels via a manual or automatic gearbox and transmission system. The Infinitely Variable Transmission (IVT), a variation of CVT, is where a pair of rollers rotate between an input and an output disc. Modifying the angle of the rollers changes the gear ratio. This transmission system is capable of handling higher torque while providing greater driving comfort and faster gear ratio changes.

Previously, Torotrak have been developing the transmission in conjunction with several vehicle manufacturers, however, the company has paid for the development of the series 3 transmission itself, after raising capital in a stock market floatation, and consequently it’s no longer bound by any confidentiality agreements and is free to show off its hard work to the rest of the Automotive industry.

The Ford Expedition is a big car. Seating up to nine, its size is staggering. North American sales of this behemoth and it’s ilk account for almost 7 million sales annually. It’s not difficult therefore, to see why Torotrak have chosen it as a demonstration vehicle and with the exception of the Torotrak IVT, a new management chip and a drive by wire throttle the 5.4l v8 Expedition I drove was completely standard.

To be honest, I wasn’t impressed with the car. The suspension was spongy and the power steering sloppy - hit a bump in the road and off you went in any direction. It was obviously not built with the winding roads of Warwickshire in mind. But I wasn’t there to judge the car.

I only knew I was driving with an IVT, and not a normal automatic, because I didn’t notice it. Accelerate and the car responds quickly. Unlike a traditional automatic there was no obvious gear changes. Unlike a traditional CVT that sees revs rise dramatically, while speed increases there was no fumbling for the right ratio. In fact after an initial rise in revs, they do start to drop while the car continues to accelerate.

It’s not only accelerating where you appreciate the IVT. Driving a tad over the speed limit on the motorway I happened to glance at the Expedition’s rev counter. It was showing a little over 1000 rpm. Almost the same as the idling speed on my own car! Consequently the ride is impressively quiet.

|

| click diagram for bigger picture |

Two separate power paths from the engine each drive separate parts of an epicyclic gear train. The first path uses direct drive through an input disc to a smaller cog within the epicyclic train, while the second path uses a unique variator to create continuous gear ratio differentials. Power is then taken from the output disc and transmitted to the larger cog of the epicyclic gear train.

Simply, the IVT is able to constantly change gear ratios to meet the requirements of the powertrain’s controller and provide the most effective ratio for most effective use of the fuel supply

Generally, IVTs are less complex than four- or five-speed automatics, with up to a third fewer parts, which makes them much smaller and lighter. IVT systems can handle higher torque and offer faster gear ratio changes than manual transmissions.

Generally, IVTs are less complex than four- or five-speed automatics, with up to a third fewer parts, which makes them much smaller and lighter. IVT systems can handle higher torque and offer faster gear ratio changes than manual transmissions.

It’s claimed, in comparison to manual systems, that that the IVT delivers, with software management of torque, speed, engine revs, reduce fuel economy by over 20% without a loss of performance, and reduced exhaust emissions. Manual gearboxes struggle to accomplish this as, for the most part, the engine will be revving too fast or slowly in relation to the speed of the vehicle to make optimum gear changes, even with manual 6-speed boxes.

Other benefits of the IVT is its unique feature on hill decent. A vehicle fitted with IVT can descend a steep gradient under complete control. Since the IVT can apply wheel torque in either direction the driver simply has to put the vehicle in reverse, marked “hill descent” on a production vehicle, and the vehicle will slowly descend the steepest of gradients. Breaking and reversing up the hill can then be done through the accelerator. This is because of the “geared neutral” where the engine is always connected to the wheels, even when the car is stationary.

Other benefits of the IVT is its unique feature on hill decent. A vehicle fitted with IVT can descend a steep gradient under complete control. Since the IVT can apply wheel torque in either direction the driver simply has to put the vehicle in reverse, marked “hill descent” on a production vehicle, and the vehicle will slowly descend the steepest of gradients. Breaking and reversing up the hill can then be done through the accelerator. This is because of the “geared neutral” where the engine is always connected to the wheels, even when the car is stationary.

2 OEMs have confirmed that the IVT is concept ready and Torotrak have signed evaluation agreements with ZF and Equos, a subsidiary of Aisin, to develop the IVT further. Of course, to manual-centric Europe, the IVT may not seem inviting. However the software can be programmed to offer a choice of "automatic IVT" or a variety of "gear selection" modes to satisfy all tastes. Torotrak realise that gaining the first foothold is the difficult part, but firmly believe that once the IVT gets onto the market it will gain acceptance. In my opinion, given my experience it’s hard to believe otherwise.

for more information visit the Torotrak Website www.torotrak.com

Added to the database on 20th January 2003

Keywords: Emissions, CVT, IVT, Gearbox, fuel, savings, transmission,